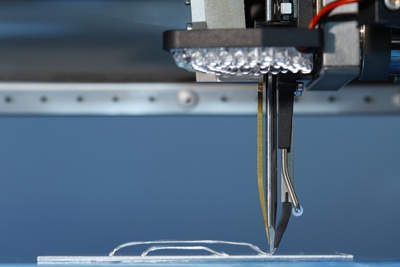

Hesse Introduces New Extreme Loop Former Bondhead for Heavy Wire Bonders to Support High Density Module Bonding

The HBK08 Bondhead supports special loop formations, fine pitch and multi-stitch bonding

Fremont, Calif., Aug 2012 – Hesse, Inc., the Americas subsidiary of Hesse GmbH, leading manufacturer of high speed fine pitch wedge bonders and heavy wire bonders for the backend semiconductor industry, has added the HBK08 Loop Former Bondhead to its BONDJET BJ935 and BONDJET BJ939 fully automatic heavy wire bonders to support growing requirements for high density module bonding. Offering highly precise die pattern recognition and bonder positioning precision, this heavy wire bondhead enables extremely long wire loops, special wire loop formations and minimal wire distances for fine pitch bonding in addition to multi-stich bonding.

Fremont, Calif., Aug 2012 – Hesse, Inc., the Americas subsidiary of Hesse GmbH, leading manufacturer of high speed fine pitch wedge bonders and heavy wire bonders for the backend semiconductor industry, has added the HBK08 Loop Former Bondhead to its BONDJET BJ935 and BONDJET BJ939 fully automatic heavy wire bonders to support growing requirements for high density module bonding. Offering highly precise die pattern recognition and bonder positioning precision, this heavy wire bondhead enables extremely long wire loops, special wire loop formations and minimal wire distances for fine pitch bonding in addition to multi-stich bonding.

The HBK08 Loop Former Bondhead enables the formation of loops or wire bridges with lengths up to 40mm and low loop heights with considerably higher wire stability than previously possible on any heavy wire bonder. A controlled bend induced into the wire by the loop former of the bondhead during the loop trajectory within <50 ms creates a considerably steeper loop fall in the back part of the wire bridge compared to conventional loop forms. With this loop formation, the distance of the wire bridge to the neighboring live circuit paths can be increased, creating a positive influence on the design rules of power modules.

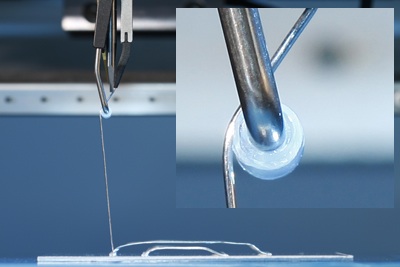

Fine pitch heavy wire bonding – for example 600 µm pitch for 400 µm wire – requires a significantly smaller wire guide. The HBK08 Bondhead incorporates a symmetrical (closed) wire guide with a 70° guide angle to implement considerably larger loops with minimal distances.

Other key features of the HBK08 Bondhead include:

- Boxlight – a coaxial illumination source attached directly to the bondhead minimizes the distance to the object being illuminated, allowing homogenous illumination of highly reflective surfaces up to a 5° tilt.

- Slim “Wire” Cutter – a specialized wire cutter developed for fine pitch heavy wire bonding incorporates a considerably steeper front-cut angle.

- Air “Wire” Cut – this feature enables “touch-free” wire cutting that eliminates surface touchdown, enabling the use of front-cut on highly sensitive chip surfaces.

- 3 Mil Wire Capability – Addressing the worldwide increase in demand for 3 mil wire, the new bondhead processes gold, aluminum and copper bonding wire with diameters from as small as 3 mil up to 20 mil (75 μm up to 500 μm).

Hesse will demonstrate the new features available on the BJ935 Fully Automatic Heavy Wire Bonder at the upcoming 45th International Symposium on Microelectronics (IMAPS) in Booth No. 210. IMAPS 2012 is scheduled for September 9 – 13, 2012 at the San Diego Town & Country Convention Center in San Diego, California, USA.

About Hesse Mechatronics, a privately held worldwide company based in Paderborn, Germany, is a leading designer and manufacturer of high speed fine pitch wedge bonders, heavy wire bonders and complementary equipment for semiconductor backend assembly. The company’s automatic wedge bonders handle both light and heavy wire applications with aluminum and gold round wire from 12.5 micron (.0005) to 500 microns (.020) in diameter, in addition to ribbon wire from 6 x 35 microns up to .3 x 2 mm, including HCR™ (High Current Ribbon). The company’s product line also includes dispensers, ultrasonic flip chip bonders, standard or customized indexers with or without handling systems, manufacturing process monitoring systems for interfacing with the company’s equipment and commercial software packages.

For more information, please visit the company’s website at www.hesse-mechatronics.com.

Editor’s Note: Caption for two images included with this release – Hesse´s new HBK08 heavy wire bondhead demonstrates extremely long loop capability