Hesse Mechatronics Launches Heavy Wire and Ribbon Bonding Services for Early Stage Product Development

Hesse Mechatronics’ West Coast Demo and Applications Lab

Adds Heavy Wire and Ribbon Bonding Equipment, Prototyping and R&D

Adds Heavy Wire and Ribbon Bonding Equipment, Prototyping and R&D

Fremont, CA, April 2013 – Hesse Mechatronics, Inc., the Americas subsidiary of Hesse GmbH, leading manufacturer of high-speed fine pitch wedge bonders and fully automatic heavy wire and ribbon bonders for the backend semiconductor industry, announces that it will offer application development, prototyping and pre-production services on a newly installed BONDJET BJ939 Fully Automatic Heavy Wire Bonder at the company’s west coast demonstration and applications lab, located at long-time company manufacturer’s representative Chalman Technologies in Anaheim, California.

The company will also offer expanded services for heavy wire and ribbon in addition to thin wire applications at its demonstration labs in Tempe, Arizona and Clinton, Massachusetts.

Heavy Wire and Ribbon on One Platform

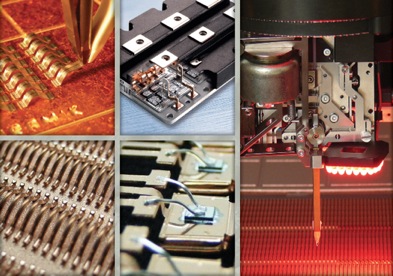

The BONDJET BJ939 heavy wire bonder is ideal for power electronics and automotive device applications. Key features and specifications include:

- Aluminum, gold, silver and copper round or ribbon wire

- 3 mil to 20 mil wire

- .075mm x .75mm to .3mm x 2mm ribbon on the same machine

- Places up to 3 wires/sec

- Integrated pull test

- Large table travel

- E-Box™ optical tool adjustment

- PiQC™ Process-integrated Quality Control measures true bond quality in real time

- In-air cut feature eliminates marking on die

In addition to providing demonstrations to customers, the company will offer early stage product development services on the BONDJET BJ939, including:

- Heavy wire and ribbon bonding process support

- Development and production of prototypes

- Pre-production manufacturing

Customers interested in heavy wire and ribbon bonding product development services should contact Michael McKeown with questions and to send samples for their applications. Mike is a wire and ribbon bonding process expert with nearly three decades of experience in the automotive and power electronics industries. He recently joined Hesse Mechatronics as senior business development manager and can be reached at info@hesse-mechatronics.us.

“We are very pleased to expand our heavy wire and ribbon bonding services to customers throughout the Americas,” notes Joseph S. Bubel, president of Hesse Mechatronics, Inc. “Our team is eager to put their expertise to work helping customers in the very early stages of new product development and support them through successful production.”

For more information on Hesse Mechatronics and its family of wedge bonders, please visit the company’s website www.hesse-mechatronics.com. For more information on Hesse Mechatronics’ training and applications support services, please e-mail info@hesse-mechatronics.us. To see wire bonding in action, visit www.wirebonddemo.com.

About Chalman Technologies

An engineering-oriented manufacturers' representative organization experienced in semiconductor, fiber optic and other microelectronics technologies, Chalman Technologies has served as Hesse Mechatronics’ rep for more than a decade. “We are pleased to partner with Hesse Mechatronics as the headquarters for the company’s West Coast Demo and Applications Lab and we are excited to offer these new heavy wire prototyping and development services,” notes Keith Chalman, VP, Chalman Technologies. “We also are proud to represent the best wedge bonder on the market.” The Hesse Mechatronics lab at Chalman Technologies is located at 3150 E. La Palma Avenue, Suite K, Anaheim, California, 92806.

About Hesse Mechatronics

Hesse Mechatronics, a privately held worldwide company based in Paderborn, Germany, is a leading designer and manufacturer of high speed fine pitch wedge bonders, heavy wire bonders and complementary equipment for semiconductor backend assembly. The company’s automatic wedge bonders handle both light and heavy wire applications with aluminum and gold round wire from 12.5 micron (.0005) to 500 microns (.020) in diameter, in addition to ribbon wire from 6 x 35 microns up to .3 x 2 mm, including HCR™ (High Current Ribbon); their heavy wire wedge bonder models also handle copper wire and ribbon. The company’s product line also includes dispensers, ultrasonic flip chip bonders, standard or customized indexers with or without handling systems, manufacturing process monitoring systems for interfacing with the company’s equipment and commercial software packages.

For more information, please visit the company’s website at www.hesse-mechatronics.com.

#