Hesse To Discuss “Wedge Bonding for Chip-On-Board and Direct-Chip-Attach Applications” at SMTA Philadelphia Chapter Meeting

Fremont, CA, May 29, 2012 – Hesse GmbH, European headquarters of Hesse Mechatronics Inc. and sister company to Americas subsidiary Hesse, will discuss “Wedge Bonding for Chip-On-Board and Direct-Chip-Attach Applications”at the rescheduled SMTA Philadelphia Chapter Meeting now on June 12th at 4:30 p.m. at the Air Products in Allentown, PA. The SMTA meeting will be conducted in R&D Building 2 in Conference Room 25. It was previously scheduled on May 9th.

In electronics assembly where packaging represents a significant cost and potential for parasitics that reduce signal integrity, Chip-On-Board (COB) and Direct-Chip-Attach (DCA) provide both a large cost advantage and reliability improvement . Wedge bonding, most commonly used for COB/DCA applications and best suited for dirtier surfaces such as printed circuit board (PCB), bonds both round and ribbon wire on the same machine with minor changeover. Heavy wire wedge bonding for high frequency applications with high throughput requirements is also used directly on PCB/laminate applications using two headed machines, one head dedicated to bonding fine wire and the other bonding heavy wire or ribbon.

The Hesse technical presentation will discuss wedge bonding for COB and DCA applications as well as metallization requirements and bond surface quality. Ribbon bonding for high frequency applications will also be discussed. Lee Levine, Distinguished Member of the Hesse Technical Staff and owner of Process Solutions Consulting, Inc. , will conduct the presentation. With more than 4 decades of process engineering experience in the semiconductor industry, Mr. Levine has been involved in the development of major innovations including copper ball bonding and loop shapes for thin, small outline packages (TSOP and TSSOP, and CSPs) as well as the introduction of DOE and statistical techniques for understanding assembly processes.

For more information on this presentation, visit http://www.smta.org/chapters/chapters_detail.cfm?chapter_id=30. For more information on wedge bonders, please visit the company’s website at www.hesse–mechatronics.com.

About Hesse Mechatronics

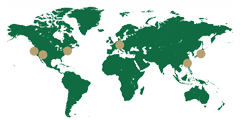

Hesse GmbH, a privately held worldwide company based in Paderborn, Germany, is a leading designer and manufacturer of high speed fine pitch wedge bonders, heavy wire bonders and complementary equipment for semiconductor backend assembly. The company’s automatic wedge bonders handle both light and heavy wire applications with aluminum and gold round wire from 12.5 micron (.0005) to 500 microns (.020) in diameter, in addition to ribbon wire from 6 x 35 microns up to .3 x 2 mm, including HCR™ (High Current Ribbon). The company’s product line also includes dispensers, ultrasonic flip chip bonders, standard or customized indexers with or without handling systems, manufacturing process monitoring systems for interfacing with the company’s equipment and commercial software packages.

For more information, please visit the company’s website at www.hesse-mechatronics.com.