Hesse Mechatronics, Inc. to Present “Why Wedge Bond” at November 10 IMAPS Webinar

Fremont, CA, October 2011 – Hesse Mechatronics, Inc., the Americas subsidiary of Hesse GmbH, leading manufacturer of high speed fine pitch wedge bonders for the backend semiconductor industry, announces that it will present an IMAPS webinar, “Why Wedge Bond,” taking place on November 10, 2011 from 12pm – 1pm. The cost is $25 for IMAPS members and $50 for non-members.

In the past, ball bonding has dominated the interconnect market because of its high speed and capabilities. However, as interconnect density is becoming greater, ball bonding is reaching its limits. Thus, wedge bonding has the potential to dominate the market for bonding ultra fine-pitch devices.

Wire bonding is an ultrasonic welding process accomplished by deforming the wire and the substrate together, forming an alloy of the two. Wedge bonding, because it directly deforms the wire without first forming a ball, is capable of producing a bond with minimum deformation and extremely low loop heights. High quality wedge bonds can produce deformation just 20-25% larger than the wire diameter, whereas typical ball bonds are 1.8-2 times the wire diameter.

Why Wedge Bond webinar participants will come away with practical knowledge of the advantages of wedge bonding over ball bonding as a reliable alternative that is capable of handling future requirements for bonding thin packages and ultra-fine pitch devices.

In addition, the webinar will cover the latest wedge bonding equipment capabilities, including improved accuracy, stitch bond speeds approaching 10 wires/second, constant loop height and constant loop length algorithms for optimum control of electrical properties, low loop capability and real-time, process-integrated quality control that measures 6 critical bond process parameters for every bond, enabling quick preventive action and an exhaustive look into the wedge bond process.

About Hesse

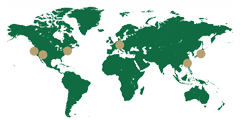

Hesse GmbH, a privately held worldwide company based in Paderborn, Germany, is a leading designer and manufacturer of high speed fine pitch wedge bonders, heavy wire bonders and complementary equipment for semiconductor backend assembly. The company’s automatic wedge bonders handle both light and heavy wire applications with aluminum and gold round wire from 12.5 micron (.0005) to 500 microns (.020) in diameter, in addition to ribbon wire from 6 x 35 microns up to .3 x 2 mm, including HCR™ (High Current Ribbon). The company’s product line also includes dispensers, ultrasonic flip chip bonders, standard or customized indexers with or without handling systems, manufacturing process monitoring systems for interfacing with the company’s equipment and commercial software packages.

For more information, please visit the company’s website at www.hesse-Mechatronics.com.